Roller Bottles are optimal in applications for large yield of cell growth and multiplication that can be used in both research and manufacturing, including the growing of mammalian cells for purposes of virus propagation and bio-product production.

Available with 2 bottle volumes of 1000ml, 2000ml

Available with 2 bottle volumes of 1000ml, 2000ml  Wide cell growth area of 490cm2, 850cm2 and 1900cm2 for adhesions and huge growth volume for suspension

Wide cell growth area of 490cm2, 850cm2 and 1900cm2 for adhesions and huge growth volume for suspension  Available in surface treated or non-treated variants

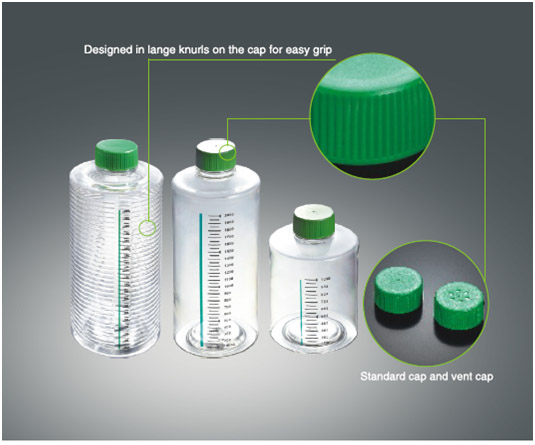

Available in surface treated or non-treated variants Designed with large knurls on the cap for easy grip

Designed with large knurls on the cap for easy grip  2 different cap styles can be used in both open and closed systems

2 different cap styles can be used in both open and closed systems  Bottle surface is smooth and free from striation to maximize usable area for growth

Bottle surface is smooth and free from striation to maximize usable area for growth  Every bottle has silk-printed graduation

Every bottle has silk-printed graduation  Suitable for all the common instruments and automation

Suitable for all the common instruments and automation  Sterilized by gamma irradiation

Sterilized by gamma irradiation  Non-pyrogenic

Non-pyrogenic

| Roller bottle 1L | Roller Bottle 2L | |

|---|---|---|

| Material | Bottle: Virgin Gamma resistant polystyrene, Cap: Virgin High Density Polyethylene | Bottle: Virgin Gamma resistant polystyrene, Cap: Virgin High Density Polyethylene |

| Volume(ml) | 1000 | 2000 |

| Packing | 24 per case, individually packed | 12 per case, individually packed |

| Purity grade(s) | Sterile, pyrogen-, DNase-, RNase-, human and bacterial DNA-free. Non-cytotoxic | Sterile, pyrogen-, DNase-, RNase-, human and bacterial DNA-free. Non-cytotoxic |

| Sterilization |  - irradiation - irradiation |

- irradiation - irradiation |

| Approx. cell growth area(cm²) | 490 | 850/1900 |

| Cap styles | Standard/ Vent | Standard/ Vent |

| Cat. No. | Volume(ml) | Surface Type | Approx. Cell Growth Area (cm2 ) |

Working Volume (ml) | Cap style | Sterile | Qty. per bag/case |

|---|---|---|---|---|---|---|---|

| TCB011001 | 1000 | Standard ,surface treated | 490 | 100-150 | Standard | Y | 1/24 |

| TCB012001 | 1000 | 490 | 100-150 | Vent | Y | 1/24 | |

| TCB011002 | 2000 | 850 | 180-260 | Standard | Y | 1/12 | |

| TCB012002 | 2000 | 850 | 180-260 | Vent | Y | 1/12 | |

| TCB031002 | 2000 | 1900 | 300-400 | Standard | Y | 1/12 | |

| TCB032002 | 2000 | 1900 | 300-400 | Vent | Y | 1/12 |

| Cat. No. | Volume (ml) | Surface Type | Approx. Cell Growth Area (cm2 ) |

Working Volume (ml) | Cap style | Sterile | Qty. per bag/case |

|---|---|---|---|---|---|---|---|

| TCB001001 | 1000 | General, Non-treated | 490 | 100-150 | Standard | Y | 1/24 |

| TCB002001 | 1000 | 490 | 100-150 | Vent | Y | 1/24 | |

| TCB001002 | 2000 | 850 | 180-260 | Standard | Y | 1/12 | |

| TCB002002 | 2000 | 850 | 180-260 | Vent | Y | 1/12 |

Roller Bottles are manufactured in accordance with ISO13485:2003 & ISO9001:2008 quality management systems in class 100, 000 clean room. Radiation protocols, Quality certificate and Certificate of Compliance are provided with every shipment upon request

| Component Material | Bottle: Virgin Gamma resistant Polystyrene , meets USP Class VI requirements. Cap: Virgin High Density Polyethylene, meets USP Class VI requirements for plastic containers and closures |

| Sterilization Assurance Level | SAL 10 ‾6. Every lot has been irradiated and dosimetrically released. Procedures for determining the dosage comply with ISO11137 |

| Non-Pyrogenic | Products are validated to have less than 0.5EU/ml |

| Cytotoxicity | All material resins are qualified using USP and /or ISO 10993 standards for cytotoxicity and have been shown to be non-toxic |

| DNase & RNase Free | Products are labeled DNase & RNase free and have been validated |

| Quality Control Testing | Representative samples have been selected from each lot and inspected according to ZK-QI |

| Tissue Culture testing | Treated samples are randomly taken from a total lot for actual perfomance test for growth with Hep-g2( Human Hepatic carcinoma cells) |

Roller bottles are packed in single package in peel to open plastic bags to assure freedom from contamination and bottle cap is individually wrapped in a package bag. Every case is printed with lot No. for quality traceability as well as expiry date. We warrant that the packaging is sufficient to protect the products against any damage during transit and storage.

Cell and Tissue culture products series are all innovatively designed by JET Engineers and manufactured under the control of ISO 9001: 2008 and ISO 13485 quality management systems. All the JET Biofil product are manufactured with 100% USP VI crystal class virgin polystyrene ( GPPS) and equal high quality polyethylene ( PE) to eliminate all extraneous materials and ensure the integrity. Furthermore, the high transparency of high class material ensures good observability. In addition, all the products are sterilized by gamma irradiation, certified DNase RNase free and non- Pyrogenic. Products are modified with vacuum gas plasma, causing the very hydrophobic polystyrene surface to become negatively charged and hydrophilic, allowing the cells to attach evenly and consistently.

BioStar offers a complete satisfaction guarantee so you can be confident of your purchasing decision. If, for any reason you are not satisfied with the product performance or service provided, we will either replace of issue a refund for the purchase price of your product.