Vacuum filters are very useful in large volume samples separation and purification.

Available with 2 different membranes-PES and PVDF

Available with 2 different membranes-PES and PVDF  Avialable with Membrane pore sizes of 0.10μm, 0.22μm and 0.45μm

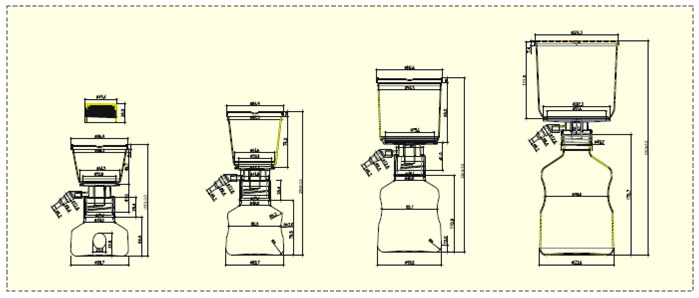

Avialable with Membrane pore sizes of 0.10μm, 0.22μm and 0.45μm  4 volumes capacities of 150, 250, 500 and 1000ml

4 volumes capacities of 150, 250, 500 and 1000ml  Light weight and heavy wall construction

Light weight and heavy wall construction  Large knurls on the reservoir bottle cap for easy screw

Large knurls on the reservoir bottle cap for easy screw  Designed wide and easy access bottle mouth for efficient and stable pour out

Designed wide and easy access bottle mouth for efficient and stable pour out  Engraved graduation ensure veracity

Engraved graduation ensure veracity  Ergonomically designed sidewalls and collar can simplify tightening/loosening and adjustments

Ergonomically designed sidewalls and collar can simplify tightening/loosening and adjustments  Designed hose connector can fit multiple hose diameters

Designed hose connector can fit multiple hose diameters  Non-pyrogenic

Non-pyrogenic

| Vacuum Filtration 150 ml | Vacuum Filtration 250 ml | Vacuum Filtration 500 ml | Vacuum Filtration 1000 ml | |

|---|---|---|---|---|

| Capacity (ml) | 150 | 250 | 500 | 1000 |

| Housing Material | ABS | ABS | ABS | ABS |

| Packing | 12 Units (1 bag/ 12 units) | 12 Units (1 bag/ 12 units) | 12 Units (1 bag/ 12 units) | 12 Units (1 bag/ 12 units) |

| Full unit overall height(mm) | 156 | 200 | 245 | 310 |

| Membrane Material | PES/PVDF | PES/PVDF | PES/PVDF | PES/PVDF |

| Membrane Diameter (mm) | 50 | 50 | 75 | 91 |

| Hold-up Volume (ml) | ≤3 | ≤3 | ≤3 | ≤3 |

| Linker and Cap Material | PP | PP | PP | PP |

| Fitting Outlet (mm) | 45 | 45 | 45 | 45 |

| Temperature(℃) | 45 | 45 | 45 | 45 |

| Purity grade(s) | Sterile, pyrogen-, DNase-, RNase-, human and bacterial DNA-free. Non-cytotoxic | Sterile, pyrogen-, DNase-, RNase-, human and bacterial DNA-free. Non-cytotoxic | Sterile, pyrogen-, DNase-, RNase-, human and bacterial DNA-free. Non-cytotoxic | Sterile, pyrogen-, DNase-, RNase-, human and bacterial DNA-free. Non-cytotoxic |

| Sterilization |  - irradiation - irradiation |

- irradiation - irradiation |

- irradiation - irradiation |

- irradiation - irradiation |

| Cat. No. | Membrane Material | Pore Size(μm) | Capacity(ml) | Membrane Diameter(mm) | Qty. per bag/case |

|---|---|---|---|---|---|

| FPE204150 | PES | 0.22 | 150 | 50 | 1/12 |

| FPE204250 | 0.22 | 250 | 50 | 1/12 | |

| FPE204500 | 0.22 | 500 | 75 | 1/12 | |

| FPE204000 | 0.22 | 1000 | 91 | 1/12 | |

| FPE404150 | 0.45 | 150 | 50 | 1/12 | |

| FPE404250 | 0.45 | 250 | 50 | 1/12 | |

| FPE404500 | 0.45 | 500 | 75 | 1/12 | |

| FPE404000 | 0.45 | 1000 | 91 | 1/12 | |

| FPV103150 | PVDF | 0.1 | 150 | 50 | 1/12 |

| FPV103250 | 0.1 | 250 | 50 | 1/12 | |

| FPV103500 | 0.1 | 500 | 75 | 1/12 | |

| FPV103000 | 0.1 | 1000 | 91 | 1/12 | |

| FPV203150 | 0.22 | 150 | 50 | 1/12 | |

| FPV203250 | 0.22 | 250 | 50 | 1/12 | |

| FPV203500 | 0.22 | 500 | 75 | 1/12 | |

| FPV203000 | 0.22 | 1000 | 91 | 1/12 | |

| FPV403150 | 0.45 | 150 | 50 | 1/12 | |

| FPV403250 | 0.45 | 250 | 50 | 1/12 | |

| FPV403500 | 0.45 | 500 | 75 | 1/12 | |

| FPV403000 | 0.45 | 1000 | 91 | 1/12 |

Vacuum filters are manufactured in accordance with ISO13485:2003 & ISO9001:2008 quality management systems in class 100,000 clean room. Radiation protocols, Quality certificate and Certificate of Compliance are provided with every shipment upon request.

| Component Material | Bottle & cup: Virgin Gamma resistant Polystyrene meets USP, Class VI requirements

Connectors: Acrylonitrile Butadiene Styrene, meets USP, Class VI requirements Cap & tube adaptor: Virgin Gamma Resistant Polypropylene, meets USP, Class VI requirements |

| Sterilization Assurance Level | SAL 10 ‾6. Every lot has been irradiated and dosimetrically released. Procedures for determining the dosage comply with ISO11137 |

| Non-Pyrogenic | Products are validated to have less than 0.5EU/ml |

| Cytotoxicity | All material resins are qualified using USP and /or ISO 10993 standards for cytotoxicity and have been shown to be non-toxic |

| DNase & RNase Free | Products are labeled DNase & RNase free and have been validated |

| Quality Control Testing | Representative samples have been selected from each lot and inspected according to ZK-QI |

| Flow rate | Flow rate has been validated for each lot in ml/min/cm2 |

Packaged in easy peel-to-open plastic bag, and receiver bottle cap is individually wrapped. Each individual unit is lot-numbered for quality traceability as well as expiry date. We warrant that the packaging is sufficient to protect the products against any damage during transit and storage.

Laboratory filtration products series, including Syringe Driven Filters and vacuum filters are designed specifically for the filtration of the culture media and organic solvents in research and industrial laboratories. They are purpose-built with features designed to bring the highest levels of performance and purity to your research. A variety of membrane types and membrane areas can be chosen that offer wide applicability with wide range of separation and purification of most liquid samples to meet different laboratory needs. The filtration products should be driven by syringe of vacuum pumps. All the products are manufactured with high quality material (ABS, PP, and GPPS) and proficient techniques which assures that they can work under pressure and still hold integrity.. In addition, all the products are sterilized by gamma irradiation, certified DNase RNase free and non- Pyrogenic

BioStar offers a complete satisfaction guarantee so you can be confident of your purchasing decision. If, for any reason you are not satisfied with the product performance or service provided, we will either replace or issue a refund for the purchase price of your product.